F.A.Q.

I see the website is pretty new but, there’s some stuff missing. What gives?

Yes, the website is brand new and is still under construction. Everything that was available before will be added back as time permits. Link To This FAQ.

Do you still do custom necks?

Yes, for a nominal fee, we’re still customizing necks. Until the custom neck section of the website is complete, please use the contact us form and we’ll take care of it via email. Link To This FAQ.

Why does it take four to six weeks to ship?

In order to offer such a large catalog of pre-designed necks, bridges and fretboards, we implement a “manufacture to order” type system to reduce the inventory required. We make necks every two to three weeks and depending on when you order, holidays, etc. it may take up to six weeks to ship. Link To This FAQ.

What’s the warranty on parts?

All parts manufactured by Birkonium llc. are warrantied for 60 days after delivery for manufacturing defects. Link To This FAQ.

Can you use wood I supply?

We are happy to work with blanks you supply, provided you understand that we cannot be responsible for defects within the wood that may appear after the part is machined. Once the order is received from the website, we’ll contact you via e-mail with shipping information

Blanks must be provided fine-sanded or planed flat and parallel on both sides to a thickness between 0.3” to .4” for fretboards, .4” to .5” for bridges. For other custom designs, the dimensions of the stock will be given to you during the design process.

Blanks that are not dimensioned, sanded and/or flattened adequately will be flattened for you at the standard shop rate of $60/hour with a 1/2 hour ($30) minimum charge.

Blanks must be oversized by 1/4″ in width and length and must be 1/8” thicker than the final dimensions of the part.

We suggest you inspect it for defects before sending. If you see any that you’d like us to try work around, please mark them. Any other orientations (e.g. top, nut end etc.) should also be marked if you have a preference.

If you are ordering an inlay, please mark the center point of the inlay on the blank using full length centerlines. If you don’t mark the center point, We’ll use our best judgement.

When working with natural products such as wood, it’s important to remember that unknown defects, knots, runout and other potential disasters can be lying just below the surface out of sight. All toolpaths are proven out before being put into production but sometimes things still go wrong. Please keep this in mind when sending wood! Also, see the prototype section below. Link To This FAQ.

Neck Information

What are the dimensions for a standard neck blank?

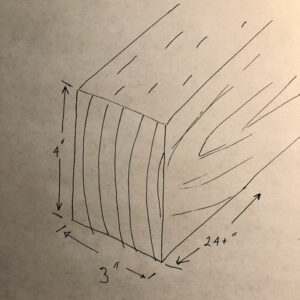

First, we require a rectangular blank to make necks. For most acoustic necks, e.g. 25.34” scale 14 fret necks or smaller, we can fit two necks on a single 24”x3”x4” neck blank. Neck blanks should be cut with the following orientation:

12 String necks, baritone necks and other necks may need a 30” or longer blank. Link To This FAQ.

I’m confused about the heel options can you explain more?

Birkonium necks are manufactured such that we can provide several different options for the neck to body join.

Dovetail (first neck in picture) – Traditional neck to body joint, can be made in two ‘heights’ Dreadnaught and OM.

Tenon – modern bolt on style. Shown without threaded inserts in the photo.

No Machining – last neck in the photo – in this case, we cut a line exactly 0.60” from

the join fret and you can machine the dovetail or tenon yourself. This is especially useful if you’re using a neck jig to align the neck angle of your guitar. Link To This FAQ.

I need a 25.4” scale neck but I don’t see that option in the filters?

No worries – that’s an artifact from the old days. What we commonly call a C.F. Martin 25.4” scale is actually a 25.34” scale and the C.F. Martin short scale 24.9” is actually 24.84” Link To This FAQ.

I’ve already roughed out the blank for my neck, can you work with this?

Unfortunately not. We have no way to index the pre cut blank for truss rod machining etc. if it’s not a rectangle. Link To This FAQ.

Fretboard Information

What is Auto Radius?

Due the the constraints of that darn Euclidean Geometry and conic sections, there are 6 parameters we can use

to define the profile of a Fretboard –

- Width at the nut

- Width at some other point

- Start Radius

- Radius at some other point

- Binding thickness at Nut

- Binding thickness at some other point.

If we define 5 of those parameters, the 6th one pops out automatically. In my current design, I’ve chosen to have the “radius at some other point” the parameter that “pops out automatically” and that the binding thickness is constant for the whole fretboard. Link To This FAQ.

Custom designs

Do you do custom work?

Yes! We do lots of custom work from inlay to body molds, to custom necks to custom solid bodies. All custom work is fit in to our normal production schedule and is treated on a first in first out basis.

If you’re ordering a custom design (e.g. inlay, mould etc.) you will receive an engineering drawing or a 3D model of your design or both. This drawing and/or model is a contract and it is up to you to evaluate the design for accuracy using the measuring tools in the eDrawings viewer or the dimensions in the drawing. If anything doesn’t look right, please speak up. I always do my best to accurately interpret the intent but breakdowns in communication happen.

Prototypes – if we become concerned about how a design will look in person, at my discretion I may offer a one time reduced price prototyping service. For a reduced price (which is determined by how much machine time the prototype takes to make) I will produce a prototype using a cheaper material for inspection before production of the actual parts begin. In some cases, a prototype may be mandatory at Birkonium llc’s discretion. Consider this option if you have a very valuable piece of stock you’d like me to machine. Link To This FAQ.

Customer Supplied Drawings / CAD files

I’m happy to work with customer supplied files and it’s a good way to guarantee that you’re getting exactly what you want while containing costs. However, depending on the tools used to make the CAD files, there can often be a lot of massaging and re-work that needs to be done. If given an estimate, please keep in mind that it was created assuming a negligible amount of work importing and cleaning up the drawings in the CAD tools that I use. If a lot of work is required to clean up the drawings cost will increase. Some tips for sending drawings:

- DXF files are best for 2D type of work

- Try to use CAD tools, NOT drawing tools to make your files. The worst files I have received that need the most clean up are those created in a drawing program and exported as DXF.